Last year I joined an Indiegogo crowd-source project for a 3D printer. I have held back on 3D prinitng because it has been advancing so rapidly. I like the Rostock type for its coolness factor and have been following the FirePick Delta as a 3D printer and Pick-and-Place machine.

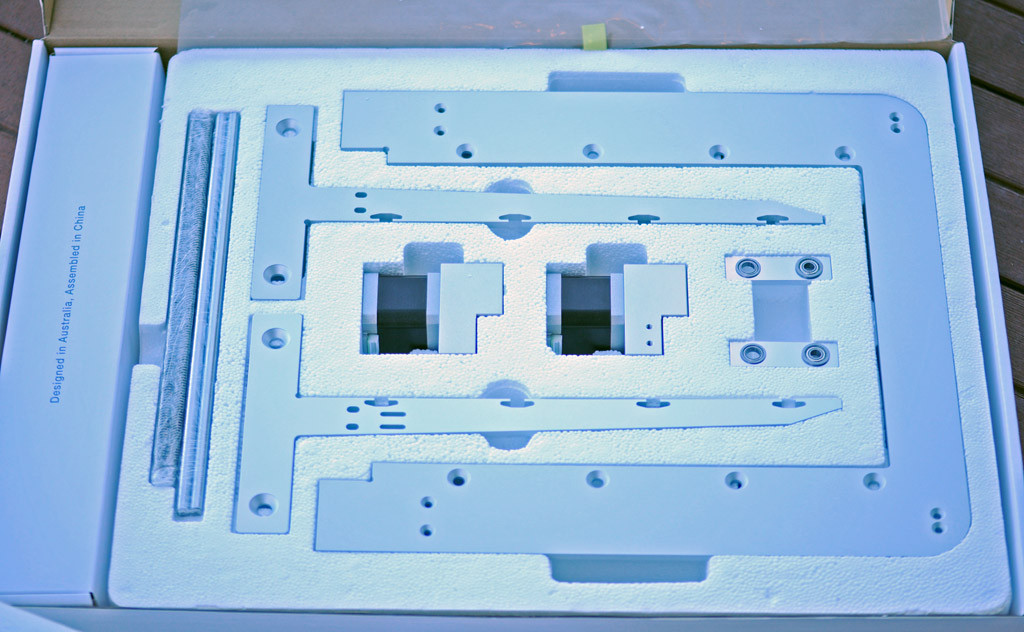

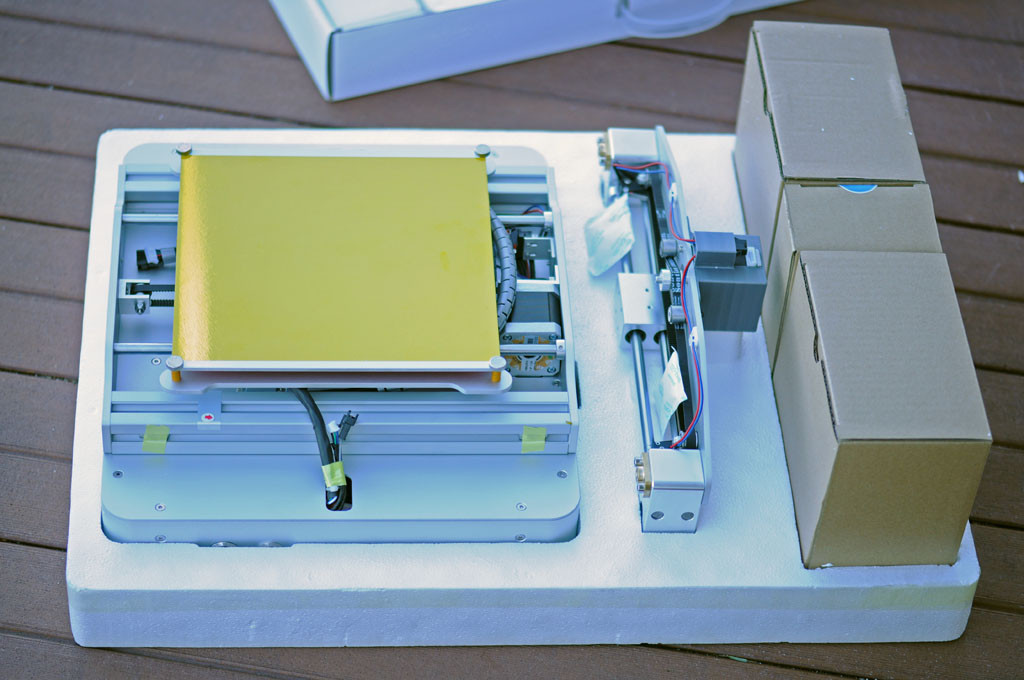

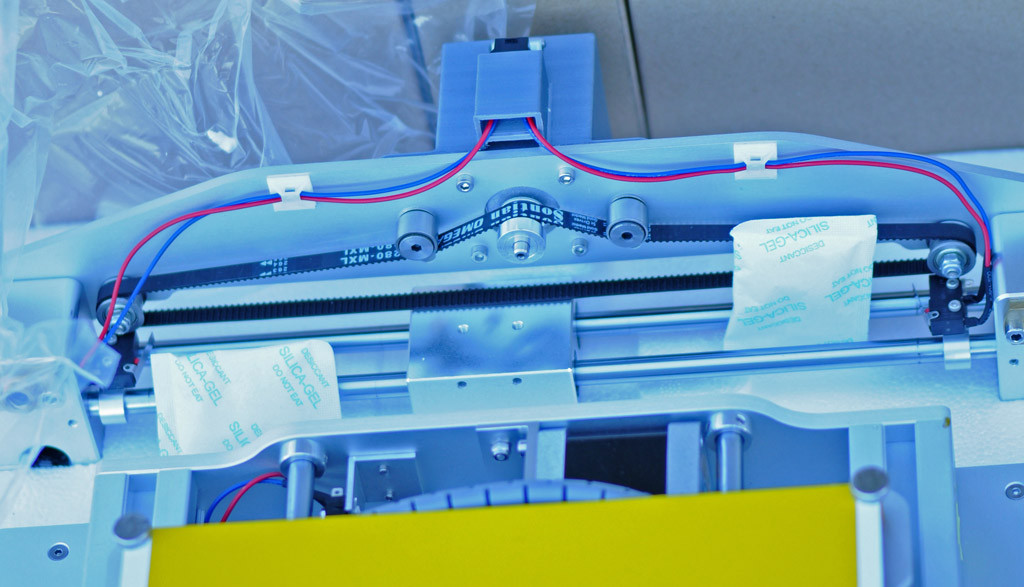

When I saw the nice industrial look of the Rapide Lite and its early-bird price (plus a handful of projects that need machined or printed parts) I decided to give it a shot. My printer came this week (Feb 21, 2015) and here is how it is packaged, which is very impressive. I dislike “unboxing” videos and blogs, so this is about the quality of the actual boxing, not the contents.

I fully realize that with software that adapts to flex and irregularities, you don’t have to use super rigid and high quality parts. And I like that a lot in some things. But when it comes to machine tools and things that can vibrate I’m still old-school and this machine is very appealing. On to assembly and test!

Here is a print in ABS of a 15cm section of Maker shape along with some slide nuts and bolts. It is a 6 hour print and is quite strong and works well. Just needs some of the angle hardware. Steel or aluminum angles and plates and bolts would be better compared to this version and I think a little smaller in size. From the cross section you can see it doesn’t really use much plastic.

Cool Uno case from djminnesota. I flipped them flat for printing and the text “ARDUINO” did not come out well. http://www.thingiverse.com/thing:737829

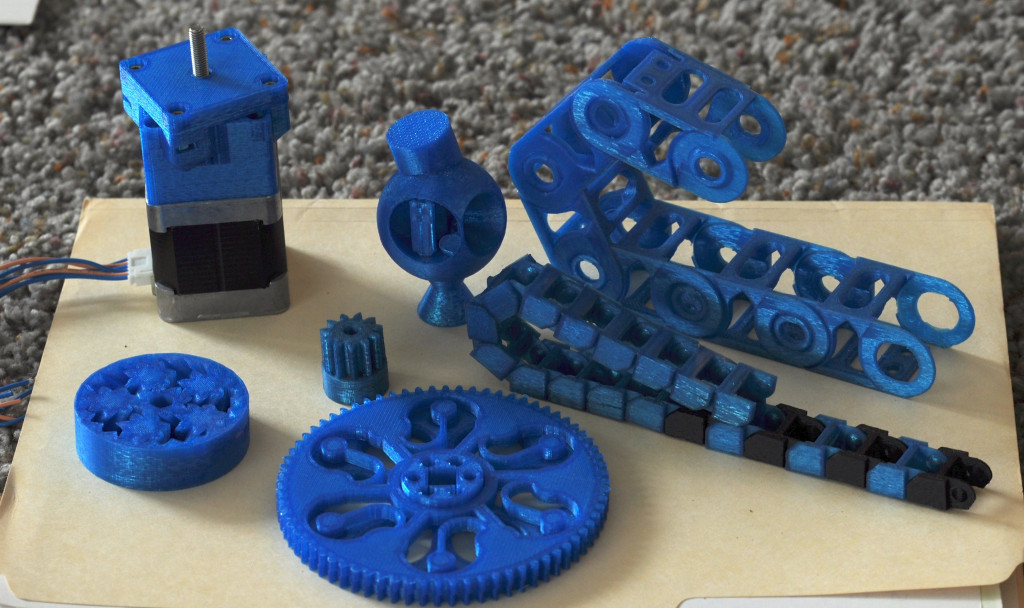

Blue parts are PLA. I got carried away with all the cable tray designs and planetary gears.

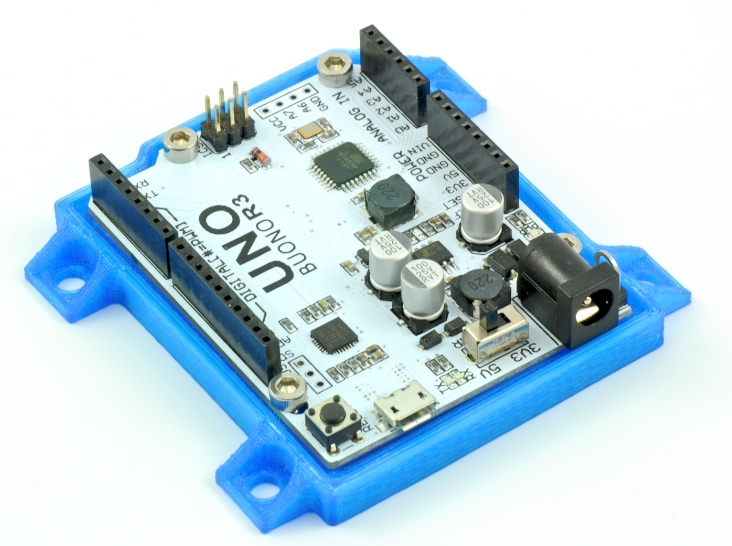

This nice Uno holder is from http://www.thingiverse.com/sceadu_design

This nice Uno holder is from http://www.thingiverse.com/sceadu_design

Some cable guides and a zero backlash gear with built in springs.

Recent Comments